China's three eye-catching battery technologies of 2020

Shanghai (ZXZC)- In 2020, several Chinese domestic power battery developers and suppliers launched innovative battery products and technologies to enhance their competitive edge. Of those, BYD's blade battery, GAC's graphene-enabled battery and SVOLT's jelly battery have caught the eye of many industry insiders. However, no matter how elaborate their technologies are, the success will eventually rest upon on cost competitiveness and the improvement of battery performance and safety.

BYD's ‘blade battery’

On March 29, BYD formally launched the “blade battery”, a new type of new lithium iron phosphate battery (LFP battery) that is set to mitigate concerns about battery safety in electric vehicles.

BYD's "blade battery"; photo credit: BYD

“The launch of 'blade battery' demonstrates BYD's resolution to thoroughly solve the pain points of NEVs and our better capability in guiding global battery industry back on track, so as to put an end to spontaneous combustions in EVs,” said Wang Chuanfu, chairman and president of BYD.

At the launching ceremony, the automaker highlighted a video of the “blade battery” successfully passing a nail penetration test, which is seen as the most rigorous way to test the thermal runaway of batteries due to its sheer difficulty.

The “blade battery” is named according to its shape, which is more flat and elongated than traditional square batteries. According to BYD, the singular cells are arranged together in an array and then inserted into a battery pack. Due to its optimized battery pack structure, the space utilization of the battery pack is increased by over 50% compared to conventional lithium iron phosphate block batteries.

The battery is firstly used in the BYD Han EV, a heavyweight model that hit the market on July 12. Powered by the “blade battery”, the vehicle offers a single-charge range of 605 kilometers (NEDC cycle).

GAC Group's three-dimensional graphene battery

GAC Group stated earlier this month that the R&D of the graphene-enhanced battery was well underway and the company expected to test the battery in production vehicles by the end of this year. Nevertheless, whether the mass production will be achieved still depends upon the testing result.

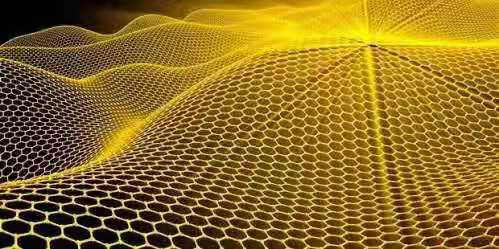

Three-dimensional graphene material; photo credit: GAC Group

During the R&D process, the three-dimensional graphene (3DG) is put into a battery's cathode and anode as an additive in a bid to improve battery charging performance, said GAC Group. The company has applied for many patents for the technology, covering fields like graphene production, supercapacitor and fast-charging battery.

GAC Group started the R&D of graphene technology as far back as 2014. At the 2020 Tech Day in July, GAC Group announced it developed super-fast-charging battery by virtue of graphene's outstanding conductivity and special 3D structure. A vehicle equipped with the battery can be recharged to 80% of its capacity within only 8 minutes and a 10-minute charging can offer a range of 200 to 300km.

If the data proves to be true, the charging time will be comparable to the refueling time of a traditional oil-fuel car.

According to GAC’s claim, the technology has been proved useful at scale of battery cell, modules and complete vehicles. It will be introduced to GAC Aion's product lineup.

SVOLT's “jelly battery”

SVOLT, an EV battery manufacturer carved out of Great Wall Motor (GWM), launched the “jelly battery” at the 2020 Battery Day held on Dec. 2, attempting to improve the battery quality through innovating in cathode and electrolyte material.

Jelly battery; photo credit: SVOLT

The battery was named “jelly” as it adopts a jelly-shaped electrolyte. According to SVOLT, this is a new lithium-ion battery that boasts high conductivity, self-healing and inflaming retarding capabilities. Thus, the heat diffusion can be prevented while the battery performance won’t be whittled down.

The "jelly battery" has a conductivity of 6*10⁻³s/cm, a heat-resistant temperature increased to 150°C, and self-healing function. In a nail penetration test, it can realize "no fire, no smoke".

The “jelly battery” is part of the “Cold Bee” solution announced at the same time. The solution still contains a thermal barrier battery pack and an EV monitoring platform dubbed “Bee Cloud”.

Based on the cell of the “jelly battery”, the developer adopts such methods as pressure relief, eruption control, cooling, alarm and heat insulation to protect the battery pack, so as to prevent the risk of thermal runaway. That is how the thermal barrier battery pack works.

Moreover, SVOLT develops the “Bee Cloud” platform which has monitored over 90,000 EVs and analyzed more than 1.6 billion data.