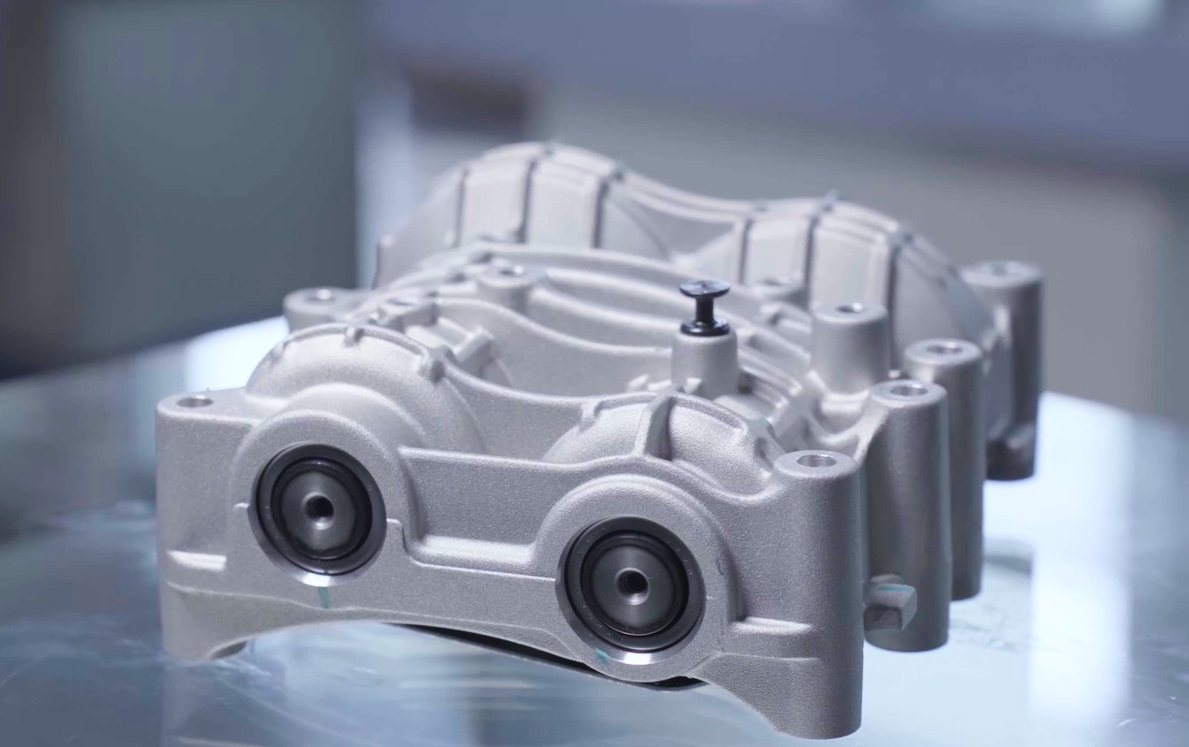

ZXZC Awards 2022 applicant: balance box assembly from Landai Technology

For the ZXZC Awards 2022, the two-piece folded tube from Gränges has applied for the Top 100 Players of China's New Automotive Supply Chain.

Photo credit: Landai Technology

Description:

The role of a balanced shaft is to use eccentric mass blocks to offset the engine first or second -order vibration caused by the piston connecting mechanism reciprocating motion when rotating. The dual-balanced shaft balance box assembly lays out two balance shafts with the center line of the cylinder in symmetrical placement. The two shaft rotates in opposite direction. The speed is twice of the engine speed, which is used to balance the second stage reciprocating inertial force of the engine.

Photo credit: Landai Technology

The problem of this design is the gear parts of the engine crankshaft transmission, due to periodic changes of sequential ignition and the insufficient of shaft rigidity lead to big torsional vibration, bringing a large partial instantaneous vibration acceleration and severe impact of gear meshing. The Balance box assy. easily creates severe gear knocking problem because of the unstable input of power. Although the vibration problem brought by the second stage reciprocating inertial force is solved, the gear knocking problem has greatly affected the NVH effect of the engine which causing decline of the vehicle comfort.

Generally, the anti-backlash gear can effectively solve the problem of knocking and screaming. The design steps of the anti-backlash gear includes the main and the auxiliary gear parameter design and the MASTA modification simulation, the C spring rigidity and Torque setting, the reasonable design of the shaft and shell backlash, the shell CAE mode analysis and structural optimization and so on.

After design finalization, it is necessary to be manufactured by precision gear processing, gear grinding and trimming, Fourier detection of gear profile and gear lead, and dust -proof environment assembly can finally guarantee the balance box product quality.

Unique advantages:

Landai Company started to develop the balance box assembly of dual -balanced shaft in 2017, breaking the technical blockade of foreign manufacturers, realizing the first domestic balance box product with fully independent intellectual property rights and forming a set of complete balance box assembly system from research and development, manufacturing, assembly, testing and testing processes. At present, we occupies the first rank of home-made balance box market share.

Application:

Suitable for various types of engines that need to reduce the vibration brought by the second stage reciprocating inertial force.

Prospect:

Fuel engine, new energy DHT model.