Autoliv's new PSS production line in Changzhou city starts operation

Shanghai (ZXZC)- Autoliv recently launched its first China-built fully automated PSS (Pyro Safety Switches) production line at its Jintan plant in Changzhou city, marking a significant step in enhancing product localization, accelerating technological innovation, and advancing industrial upgrades, the company announced on Aug. 27 via its WeChat account. This development is also a crucial milestone in Autoliv's strategy to respond to local market demands and intensify its localization efforts in China.

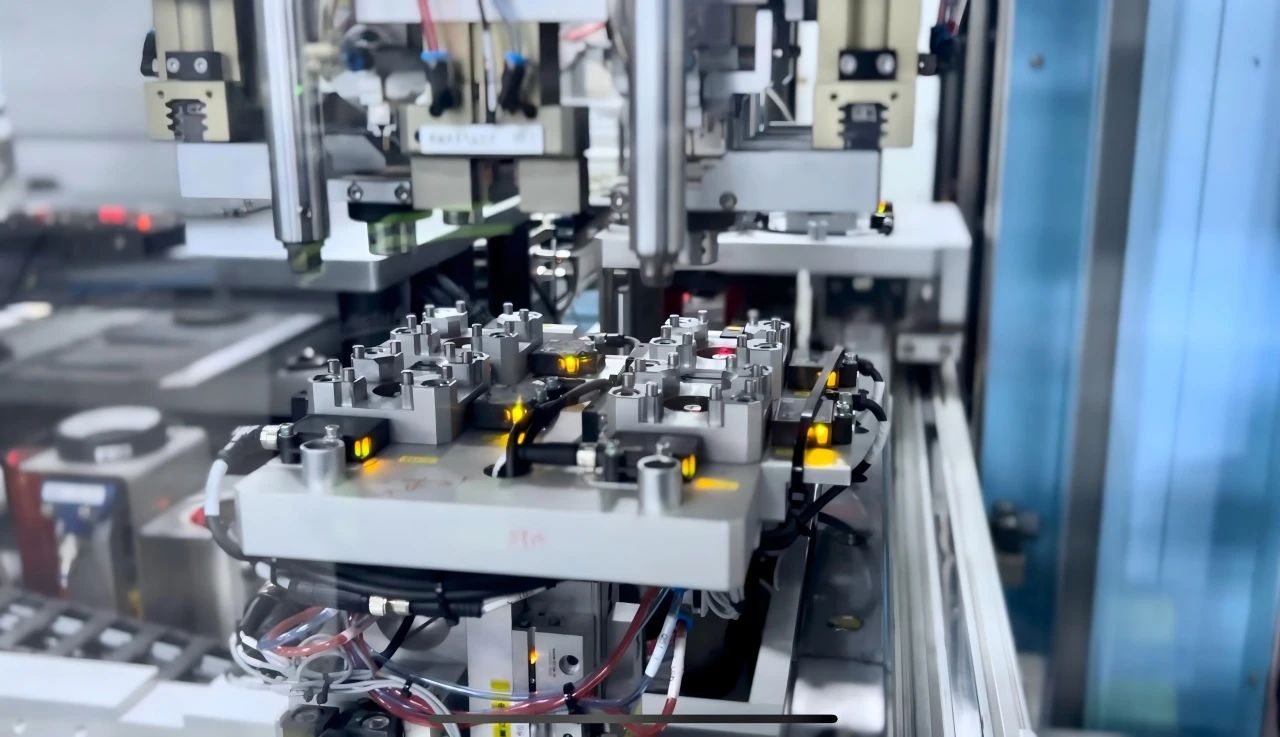

Photo credit: Autoliv

Autoliv said is committed to offering tailored solutions that cater to industry developments and customer needs. Addressing public concerns about the risk of electrical fires and electric shocks following electric vehicle collisions, Autoliv has introduced its PSS product line, designed to manage the high voltage required for long-range electric vehicles, with capabilities of up to 1,000V. These switches can cut off abnormal or short-circuit currents within milliseconds, significantly reducing potential hazards.

According to Autoliv's introduction, the PSS utilizes pyrotechnic materials as the power cut-off mechanism. Upon receiving a trigger signal, an internal ignition device lights the pyrotechnic material, causing a rapid chemical reaction that generates a large volume of gas. This gas then drives a piston rod to sever the copper busbar, effectively cutting the circuit. The PSS boasts several advantages, including resistance to aging, zero energy consumption during operation, immunity to vibration, low internal resistance, and a consistent response time of less than 2 milliseconds from signal reception to circuit interruption. These features make the PSS an invaluable component for ensuring high reliability in safety systems.

Autoliv noted that its PSS production line incorporates cutting-edge automation technology and intelligent manufacturing concepts. From raw material intake to finished product output, every stage of the process is highly automated and intelligent. Precision robotic arms skillfully perform assembly and inspection tasks, while smart sensors continuously monitor the production environment to ensure strict adherence to quality standards. This efficient operation results in the production of one high-quality PSS every ten seconds, with annual output easily surpassing the one-million-unit mark.