Advancing power battery technology: review of Chinese firms’ breakthroughs in 2021

Amongst the rapid growth in NEV outputs and sales in China, both battery makers and NEV manufacturers are attaching greater importance to the quality of power batteries as they all know the core part is crucial for more market share. Thus, they are dedicated to innovating in battery technologies from multiple aspects, such as chemistry, battery management system, energy density, and electrode materials.

Notably, some companies work on battery technology innovation for the sake of sustainable development as they are trying to find proper alternatives in case of future shortage of lithium resources.

Let's step back and take a look at what innovative technologies and breakthroughs were made for automotive power batteries in China in 2021.

CATL launches first-generation sodium battery

CATL unveiled the company's first-generation sodium-ion battery on July 29, 2021. The company revealed in late Dec. 2021 that it had already kicked off the deployment for the industrialization of sodium-ion batteries and expected a relevant industrial chain to basically take shape in 2023.

Sodium offers similar properties to lithium and can also be used as a charge carrier between a battery’s cathode and anode. Nevertheless, compared to lithium ions, sodium ions feature a larger volume and higher requirements regarding structural stability and the kinetic properties of materials, leading to a bottleneck for industrialization of sodium-ion batteries.

CATL's first-generation sodium-ion battery; photo credit: CATL

Through many years of R&D, CATL has developed proper electrode materials to solve the aforesaid problem. In terms of cathode materials, the company said it has applied Prussian white material, whose bulk structure was redesigned by rearranging electrons, in a bid to solve the problem of rapid capacity fading upon material cycling. Regarding anode materials, CATL has developed a hard carbon material that features a unique porous structure, which enables the abundant storage and fast movement of sodium ions, and also an outstanding cycle performance.

CATL said its first-generation sodium-ion battery cell can achieve up to 160Wh/kg of energy density, and the battery can charge in 15 minutes to 80% SoC at room temperature. What’s more, in a low-temperature environment of -20℃, the sodium-ion battery has a capacity retention rate of more than 90%. The strong low-temperature performance could make up the deficit to lithium-ion cells, which will be confronted with a significant fading in cold climate.

Moreover, sodium-ion cells can be produced in a larger quantity at a lower cost as sodium resource is far more abundant than lithium. This reason also makes them potentially promising in the energy storage market—a segment that demands less battery weight and energy density—where CATL attaches great importance as well.

Regarding the innovation in battery system, CATL developed the “AB” solution, which is to mix and match sodium-ion and lithium-ion batteries in a certain proportion and integrate them into one battery management system. This aims to leverage the advantages of both chemistries—combining the great low-temperature performance of sodium-ion with higher energy density of lithium-ion cells.

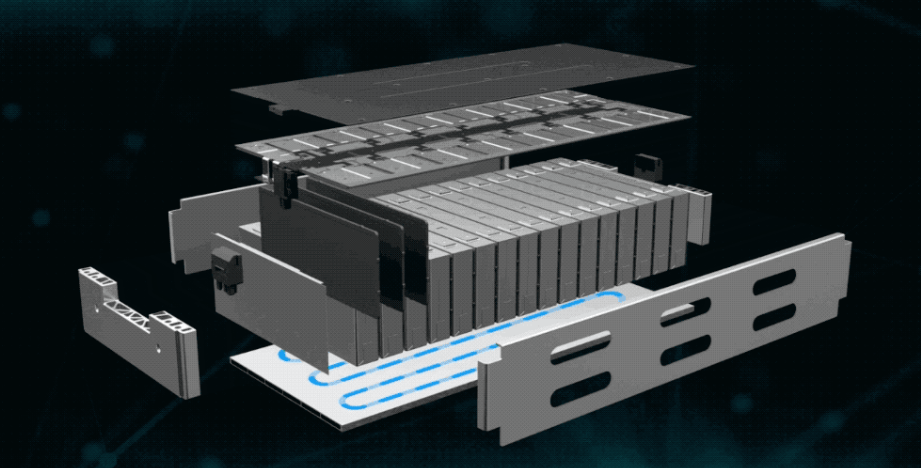

CALB launches One-Stop Bettery technology

CALB, short for China Lithium Battery Technology Co., Ltd, announced last September the launch of the One-Stop Bettery technology, which is developed to remarkably improve the power battery production manufacturing efficiency.

Photo credit: CALB

The idea of "Bettery" comes from the words "Better" and "Battery", which means "making better and better batteries".

According to Xie Qiu, general manager of CALB's passenger vehicle business, the company set forth the “One-Stop” idea based on the product design and manufacturing requirements for high integration and minimalism, and the demands for high specific energy, high safety, and low cost.

By exploring and applying the “One-Stop” idea, the integration and manufacturing efficiency for batteries are greatly improved as many existing physical bottlenecks about series process and structural composition will be removed. Besides, guided by the technical idea, products will have simpler structure and fewer components, so that the product reliability and manufacturing efficiency will be significantly enhanced, said Xie Qiu.

He also noted the “One-Stop” idea is available for both cells and battery packs.

The product with the “One-Stop Bettery” technology, which supports 700km range for LiFe and 1,000km range in ternary, is expected to be introduced to the market in June 2022.

Gotion High-Tech makes breakthroughs in battery energy density, semi-solid-state battery R&D

In 2021, Gotion High-Tech successfully made ternary lithium cells with an energy density of up to 300 Wh/kg installed in complete vehicles, Cai Yi, Dean of the company's Engineering Research Institute, said in mid-Dec. of last year.

Mr. Cai also unveiled Gotion High-Tech has made breakthroughs in the development of 230Wh/kg LFP (Lithium iron phosphate batteries) battery and 110Ah semi-solid-state battery.

Photo credit: Gotion High-Tech

Gotion High-Tech's chairman Li Zhen said last Nov. at an industrial forum that the company will “supply a local manufacturer of high-quality pure electric vehicles with a semi-solid-state battery that will enable a range of 1,000 kilometers”.

Moreover, Gotion High-Tech presented in Jan. 2021 a 210Wh/kg LFP pouch cell that uses silicon-based anode. The new product was set to be put into mass production at the end of last year, a local media outlet unveiled in Sept., citing Xu Xingwu, executive vice president of Gotion High-Tech Engineering Research Institute.

SVOLT sees cobalt-free battery used in production model, develops 2nd-generation short-blade LFP battery

SVOLT, the power battery manufacturer carved out of Great Wall Motor (GWM), announced last July the beginning of series production of its proprietary novel nickel-manganese (NMX) battery cells at a plant in Jintan District, Changzhou City.

The milestone made SVOLT the world's first power battery firm that achieved volume production of cobalt-free batteries.

SVOLT said it is initially producing two sizes of its NMX batteries: 115 Ah in a format compatible with Volkswagen's Modular Electric Drive Toolkit (MEB) platform and a long 226 Ah format.

According to SVOLT, the aforesaid NMX batteries use the company's in-house developed NMX cathode material (75% nickel and 25% manganese). Mass production of the cathode material has been running since April 2021.

Thanks to the exclusion of heavy metal cobalt and the lowered nickel content, SVOLT's cobalt-free NMX cells are not only more sustainable, but also about 5% cheaper than conventional NCM cells, according to the company.

SVOLT also made great efforts to improve the cycling ageing and calendar ageing of the NMX cells compared to classic NCM ones, resulting in more than 2,500 charging cycles.

SVOLT's cobalt-free battery pack shown at 2021 Chengdu Motor Show; photo credit: SVOLT

Then in August 2021, SVOLT unveiled at the 2021 Chengdu Motor Show its first production cobalt-free NMX battery pack. Meanwhile, the battery maker announced the product had been installed in the GWM's ORA Cherry Cat, which was also showcased at the show.

The battery pack used by the ORA Cherry Cat is the 150Ah version, capable of 82.5 kWh and 170Wh/kg of energy density. It can offer the model a range of over 600km at a normal temperature.

SVOLT introducing Short Blade battery products at 2nd Battery Day; photo credit: SVOLT

Regarding the improvement of battery energy density, SVOLT has already fulfilled the development of the second-generation L600 short-blade LFP battery, which is expected for volume production in the third quarter of 2022, Yang Hongxin, Chairman and CEO, said in Nov. 2021.

The second-generation short-blade LFP cells have the same specifications as the first-generation one, but the unit capacity is increased to 196Ah (versus 184Ah for the first generation), the gravimetric energy density exceeds 185 Wh/kg, and the volumetric energy density tops 430Wh/L.

Great Wall Motor launches ‘Dayu’ battery for higher battery safety

In late June 2021, at GWM's 8th Tech Festival, the automaker launched its next-generation power battery dubbed “Dayu” (or “Yu the Great”), whose technical patents have been open to the whole auto industry for free.

GWM displaying technical structure of "Dayu" battery; photo credit: GWM

The new battery technology is named after a legendary king who was famed for taming the prehistoric floods in ancient China.

Instead of damming the torrential floods, Dayu chose to introduce floodwaters into fields by dredging the riverbeds and building a system of irrigation canals. His wisdom inspired GWM's R&D persons when they worked on improving battery safety.

To prevent firing or explosion, carmakers and battery makers usually focus on insulating problematic cells from neighboring ones. GWM engineers found out a novel method that allows the heat of failing cells to leave the battery pack as quick as possible to avoid extreme temperature and thus prevent disastrous results, Cao Yongqiang, the battery design director of GWM, said last Sept. at an event held to demonstrate how the Dayu battery works.

GWM revealed batteries using the “Dayu” technology will be installed in its vehicles from 2022.

GAC AION unveils 'magazine' battery tech, super-speed battery tech, sponge silicon anode tech

GAC AION, the NEV-dedicated subsidiary of GAC Group, last year launched a slew of battery innovative technologies, including the “magazine” battery system safety technology (called “magazine battery” for short), the super-speed battery technology, as well as the sponge-silicon-anode-based battery.

Magazine battery technology; photo credit: GAC AION

Launched on March 10, 2021, the magazine battery is designed to enhance power battery safety by virtue of four core technologies, namely, the battery cells capable of ultra-high heat resistance and stability, the battery safety cabin with great heat insulation performance, the ultra-fast cooling system, as well as the fifth-generation battery management system capable of round-the-clock control, said the company. Thanks to those technologies, the battery will be as safe as being placed in a safety cabin shaped like a magazine.

Compared to normal battery pack, the one equipped with the magazine battery technology will has its volumetric energy density increased by 9.4%, gravimetric energy density increased by 5.7%, while the cost deceased by 10%, according to GAC AION.

Left: super-speed charging battery technology; right: A480 supercharging pile; photo credit: GAC AION

On Aug. 30, GAC AION officially launched its super-speed charging battery technology that makes an EV charged at the fastest charging rate of 6 times compared to existing technologies.

Speaking of the working principle of the new technology, the company said by virtue of the innovation and upgrade of anode and cathode materials, electrolyte, membrane, and conductive agent, the migration and embedding process of lithium ions will be greatly quickened and the electric conductivity will be improved, so as to enhance battery's charging speeds.

The super-speed battery technology can enable batteries to work under a voltage of up to 880V and withstand a recharge rated at up to 480kW. Besides, a five-minute charge can support a range of over 200 kilometers.

GAC R&D Center's executive intruducing sponge silicon anode technology at GAC Tech Day; photo credit: GAC AION

In April of last year, the GAC Tech 2021 saw the unveiling of GAC's sponge silicon anode technology. This technology can make the silicon negative sheet inside the battery as soft and elastic as a sponge, strengthening it against wear and tear from charging and giving it a larger storage capacity. Using the technology, the volume and weight of a single battery can be decreased by 20% and 14% respectively.

The sponge silicon anode technology was applied in the AION LX Plus first, which hit the market on Jan. 5, 2022 and drew the industry’s attention with a CLTC-rated range of over 1,000km.