Polestar sets an example in reducing lifecycle CO2 emissions

More and more countries are setting carbon-neutral targets as part of their commitment to solve environmental problems. China announced that it will strive to peak carbon dioxide emissions by 2030 and achieve carbon neutrality by 2060 during the 75th annual U.N. General Assembly. In order to fulfill the promise, the government has made it a key mission for 2021 to effectively perform work for peak carbon and carbon neutrality.

As was expected, carbon neutrality has become a hot topic during the annual two sessions, and undoubtedly, a milestone that automakers endeavor to achieve. As a pillar industry of the national economy, auto industry is also a main source of carbon emissions for vehicles produces a large amount of emission throughout the entire life cycle, from materials production, manufacturing and logistics, the cars’ use phase, and the end of life. Although China has made it a strategy to develop new energy vehicles, those vehicles have their own environmental problems.

Carbon emissions should be assessed throughout the entire life cycle.

Car manufacturers have not been clear in the past with consumers on the environmental impact of their products. Car manufacturers are not being transparent. Polestar is the first EV brand to release its Life Cycle Assessment (LCA) in Sep.2020. And Polestar revealed a truth that at current stage, manufacturing an electric vehicle produces no less carbon emissions than making an internal-combustion one.

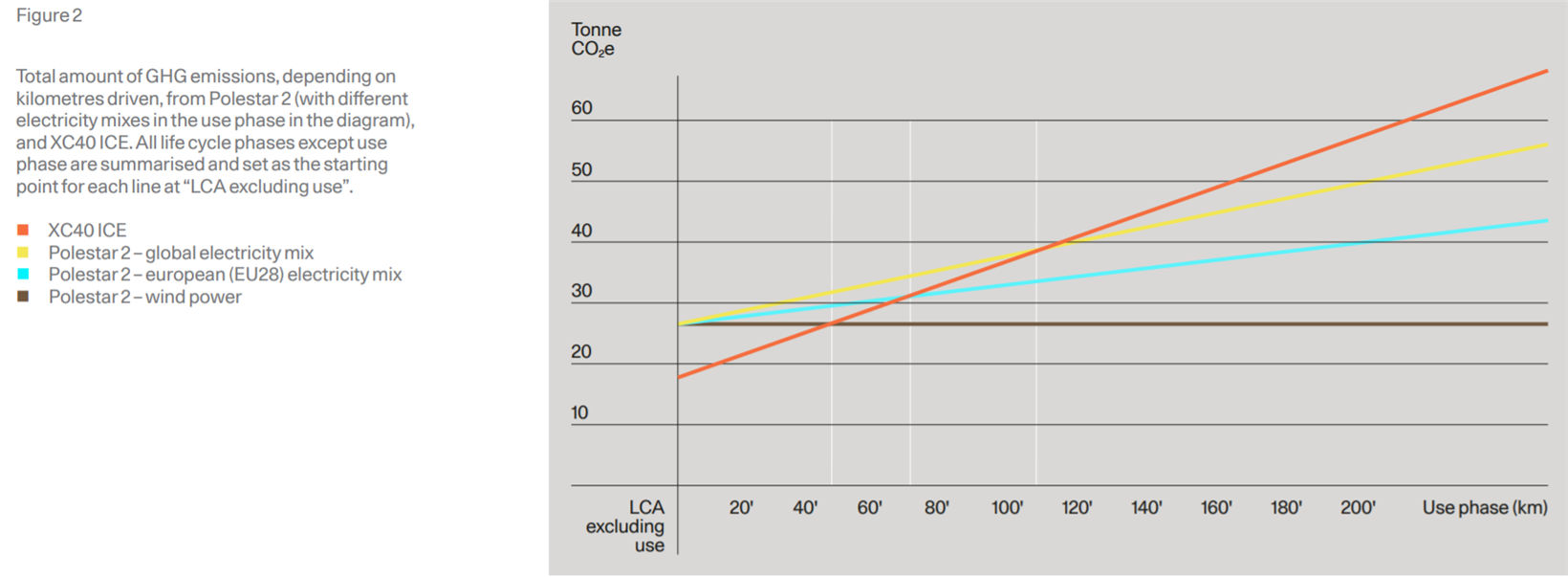

Take the Polestar 2 as an example. According to the LCA report, production of an all-electric Polestar 2 makes 26 tons of CO2, because its high-density battery pack results in higher carbon emissions than a conventional vehicle. But after running 50,000 kilometers, the electric vehicle can match a conventional car in carbon footprint if it is charged with electricity from renewable energy.

Photo Credit: Polestar

So the main problem for the moment is to reduce the emissions from the manufacturing, logistics and scrapping of an electric vehicle. And Polestar’s mode may be a good example for other players.

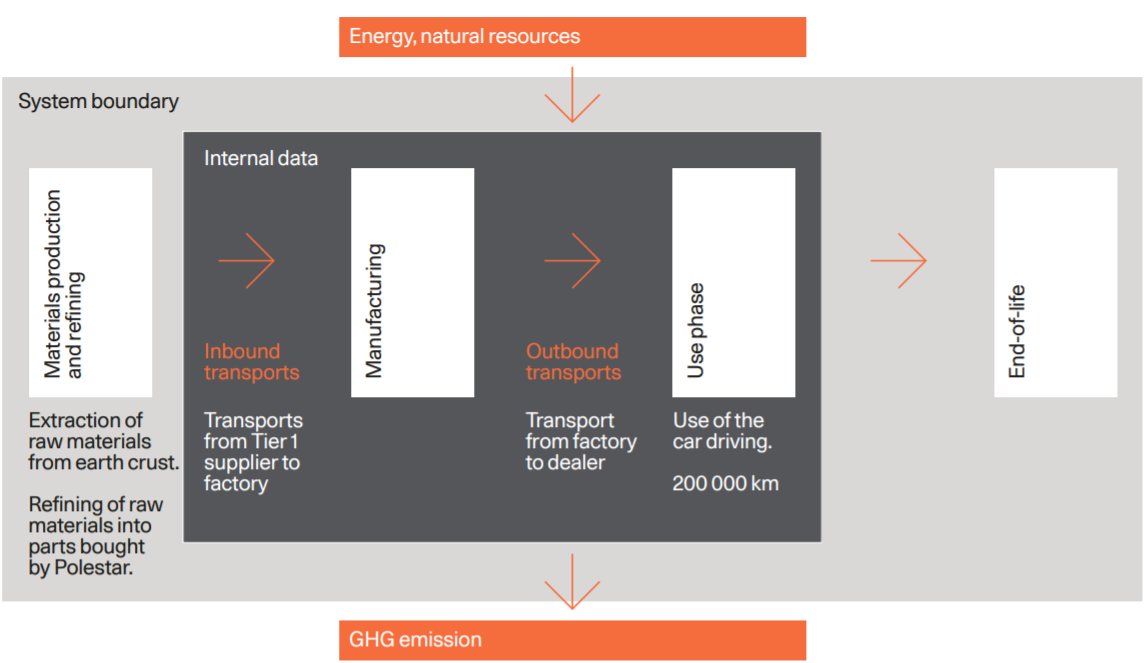

To Polestar, it is essential to track the emission level throughout a vehicle’s life cycle, including emissions from materials production, manufacturing, the use phase of the Polestar 2, and its end of life. As a result, Polestar adopted the LCA method to measure the environmental impact of a vehicle.

Schematic description of the studied system and its different life cycle phases. Photo credit: Polestar

In terms of materials, Polestar adopts full vegan in vehicle interior. For example, the company replaces leather with its Weave Tech, which is entirely free of animal products, in the Polestar 2’s interior. It’s a water-based (not solvent-based), dirt and moisture resistant, modern PVC material inspired by divers’ wetsuits. The chemists and interior designers have reduced the amount of phthalates down to 1%, compared to an industry standard of 35-45%, making it much more health and environment friendly. Besides, the material can also help to reduce the vehicle’s weight by 7.5 kilograms.

As to the manufacturing, the company’s production center in Chengdu runs on 100% renewable electricity. Around 65% of the electricity used there is hydroelectric while the rest comes from solar, wind and other renewable sources. And the factory has no industrial water discharge and is adopting a circular approach to deal with waste, including the recycling of its waste carbon fiber material and reduction of landfill waste. In the future, the plant which makes the Precept will also be powered by 100% renewable electricity to achieve carbon neutrality.

Polestar’s production center in Chengdu. Photo credit: Polestar

What’s more, Polestar also use the blockchain to trace raw materials it uses in vehicles to make sure that they come from reliable suppliers.

Carbon emissions from the transport of vehicles need to be reduced.

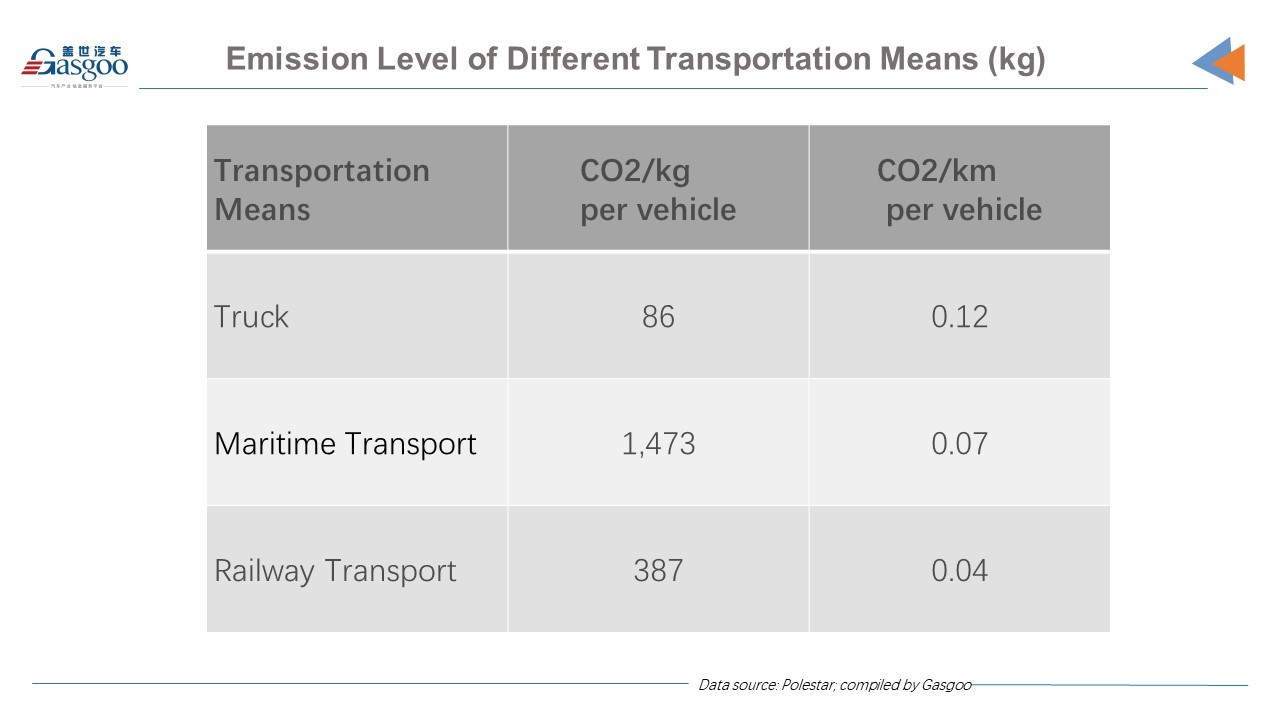

In spite of the measures taken to cut the carbon emission from raw materials, manufacturing and usage, there are still some drawbacks in the logistics of vehicles. At the moment, transport of lithium-ion batteries by railway is restricted by China so companies have to use maritime transport for long-distance logistics and exporting of electric vehicles, rather than railway transport which boasts many advantages in cost and emission.

In July, 2020, Polestar started the delivery of the Polestar 2, made in its Luqiao plant in China, in such European countries as Sweden, Norway, England, Germany. And now the company is expanding its retail presence across the United States with plans to open new locations in 15 cities by the end of 2021.

Li Shufu, chairman of Zhejiang Geely Holding Group, made a proposal during the annual two sessions to facilitate the group’s push in global market. The proposal says that relevant railway transport regulations should be revised in accordance with the distinct features of electric vehicles, and that special railway trains should be offered for transport of new energy vehicles to help local companies go global and meet the increasing demands of the NEV market in Europe.

Potential risks are the main reason for banning railway transportation of lithium-ion batteries, but in recent years, the safety level has been lifted as automakers has put more weight on the safety of new energy vehicles and the industry saw improvement in technologies and manufacturing standards. And thanks to the business-friendly EU regulations, European automakers has begun long-distance logistics of electric vehicles by railway transportation.

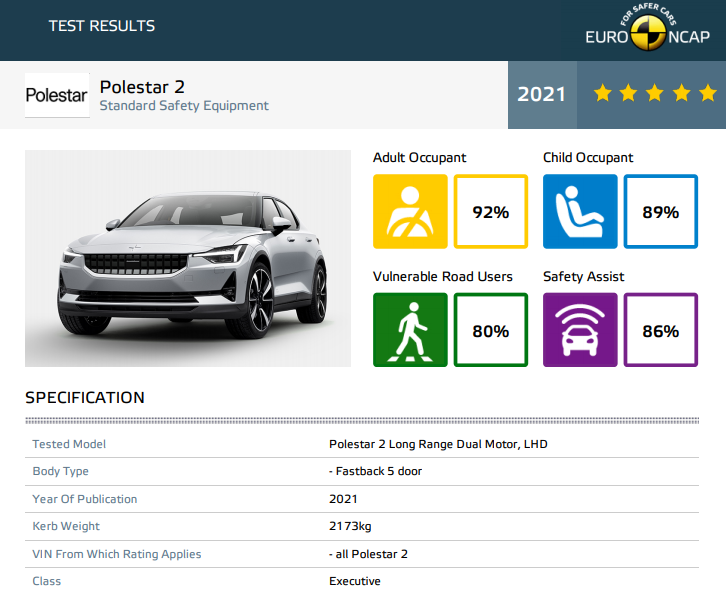

Polestar 2 achieves five-star rating in the Euro NCAP test. Photo credit: Polestar

Besides, safety of new energy vehicles also lies in product design, manufacturing techniques and quality management. Recently, the Polestar 2 received the maximum five-star rating in the Euro NCAP crash test and became one of the safest electric vehicles ever tested by Euro NCAP.

In a word, as a performance car brand whose products are made in China and sold to the global market, Polestar has higher requirements for inter-continental logistics and is much more concerned about the carbon emissions produced in the transportation of vehicles. At the same time, Polestar suggests that uniform methodology should be adopted across the industry to assess vehicles’ carbon emissions throughout the entire life cycle and that industry-wide transparency is in the best interests of everyone: consumers, manufacturers, and the environment.