Jinkang New Energy intelligent plant starts trial run

Shanghai (ZXZC)- Chongqing Jinkang New Energy Automobile Co., Ltd has currently put its intelligent plant located in Chongqing into trial operation, according to local media.

The Jinguo (Chinese character 金菓) EV SF5—the first model produced by the plant will reportedly have its first batch of prototype cars roll off the production line at the end of this year and become available for pre-order in the second quarter next year. The new model is expected to hit the market as early as the third quarter in 2019.

Involving a total investment of RMB2.5 billion and based on Germany Industrie 4.0 standard, the automaker's intelligent plant utilizes a cooperative system that can digitalize and intelligentize the information of supply, manufacturing and sales.

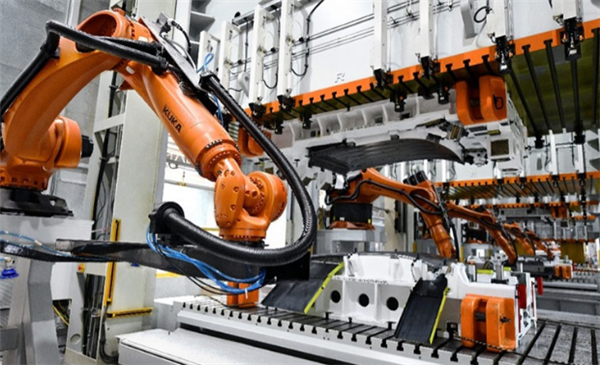

According to relevant reports, the Chongqing-based plant will deploy over 800 robots around stamping, welding, painting and assembly workshops. They are used in such manufacturing links as welding, coating, transferring between stations and bulky material loading, etc.

Intelligentization is another bright spot for the plant. AGVs (automatic guided vehicles), boasting abilities of material identification, adaptive memorization and self-learning, are employed to transport manufacturing materials like auto parts. In addition, the manufacturing command center is run by a “digital brain”, which is able to analyze and judge the real-time production conditions, arrange manufacturing plans and make plans be implemented.

Moreover, on the basis of industrial Internet, the plant integrates such modular systems as R&D, tailored design, production and logistics, which makes information be shared among various sectors including product, facility, assembly line, workshop and the whole plant and available for unification of management.