Chinese home appliance giant Midea unveils multiple core components for EVs

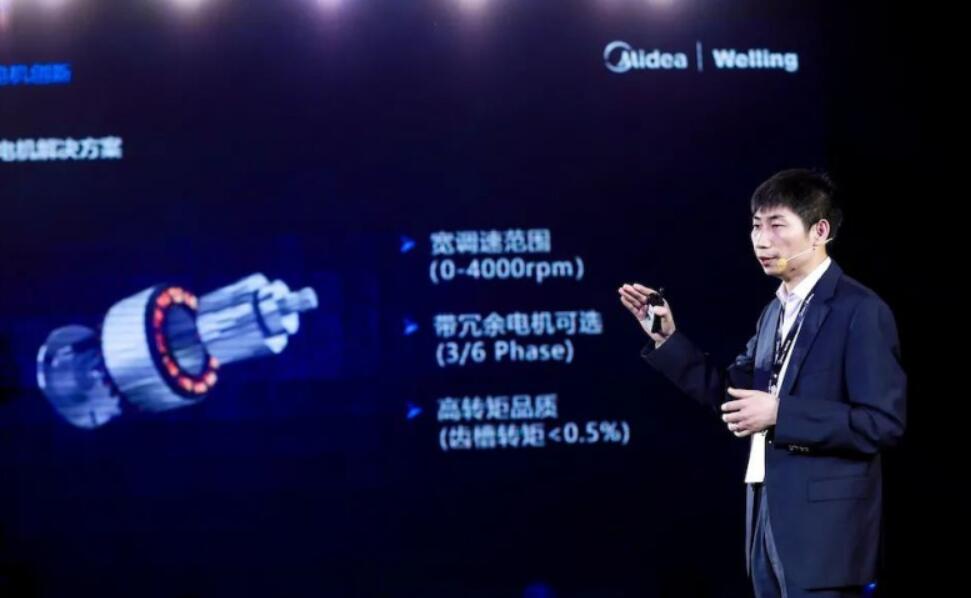

Chinese home appliance giant Midea Group's wholly-owned subsidiary Welling Holding on Tuesday unveiled three major product lines, including drive systems, thermal management systems and assisted driving systems.

Unlike technology companies including Xiaomi, Baidu, and Qihoo 360, Midea particularly emphasized that it is not directly involved in building cars, but focuses on providing components for car companies.

Midea has always been seen as a company focused on home appliances, so why is it making car parts?

"I think Midea should play its manufacturing ability and quality control ability in the field of home appliances. Especially in the last six months, the supply chain has become a headache for many car companies, and we want to be the fastest responding supplier in the industry to keep up with the speed of car companies," said Fu Congjun, president of Midea's electromechanical business group.

Welling is mainly involved in the three product lines of drive system, thermal management system and assisted driving system, and has already completed mass production of products and cooperated with traditional and new power car companies.

The drive motor system of new energy vehicles is the core key component, and excellent motor technology can improve vehicle power performance and energy consumption performance.

Welling released a high-efficiency drive motor with high power density, which can reach 16,000-20,000rpm.

The automotive thermal management system is the strength of Midea, which produces 140 million units of fully enclosed air conditioning compressors in 1 year.

"The foremost problem with new energy vehicles is mileage anxiety, especially in winter, when the range loses a third after the air conditioner is turned on. That's the biggest reason why people don't choose new energy vehicles," said Chen Jintao, general manager of Midea Welling Automotive Components.

Therefore, Welling developed the electric compressor to alleviate the current pure electric vehicle driving range anxiety problem.

Its CO2 electric compressor adopts an environmentally friendly CO2 refrigerant, which can achieve high heating efficiency under extremely cold working conditions and solve the problem of rapid battery recession in extremely cold and low-temperature environments.

Compared with the traditional mechanical structure, the EPS steering motor electronic steering without mechanical delay, fast response time, is a key component in intelligent driving. Fu said that Midea began to develop EPS motor ten years ago.

In fact, this is not Midea's first foray into the automotive field.

Midea announced its entry into the commercial vehicle sector in 2003, and has since acquired several bus companies and built new production bases in Kunming and Changsha, with a capacity of 10,000 complete buses and special chassis.

Midea also acquired Beijing Hiconics Drive Technology through its subsidiary in March last year to increase its new energy vehicle layout.

Analysts say China's smart car industry's 'Warring States Era' has just begun